Transportation Pooled Fund Project TPF-5(226) was led by the Virginia

Department of Transportation. Other project members included New York,

Iowa, Texas, and the Federal Highway Administration.

| |

| |

|

Steel bridge fabrication procedures strive to deliver a bridge that fits

together as-designed during erection. To minimize fit-up issues during

erection, most fabricators employ a match-drilling process. Using this

method, girder holes are drilled to fit with a standard pre-fabricated splice

plate in order to ensure proper alignment. This method of fabrication is,

however, labor and space intensive. Typically, holes can’t be machined into

steel plates in the most efficient manner. Holes are now drilled in a fully

fabricated girder with the web attached to the flanges, as opposed to placing

holes in flat plates using more efficient drilling equipment. In spite of

using current match-drilling procedures to guarantee alignment, there are

still fit-up issues during erection. The goal of this project was to develop

new tools and methods that improve current manufacturing processes and quality

control (QC) during fabrication. These tools and methods provide much greater

and more accurate information than current practices that rely on manual

measurements. This project has developed and deployed a

BRIDGE VIRTUAL ASSEMBLY SYSTEM (BRIDGE VAS) that improves current steel

bridge fabrication processes. More reliable and more accurate information

on what is being fabricated will produce a better quality end-product,

benefiting both fabricators and bridge owners. The BRIDGE VAS eliminates

the need to match-drill girders and has the potential to reduce fit-up issues

during erection.

|   |

|

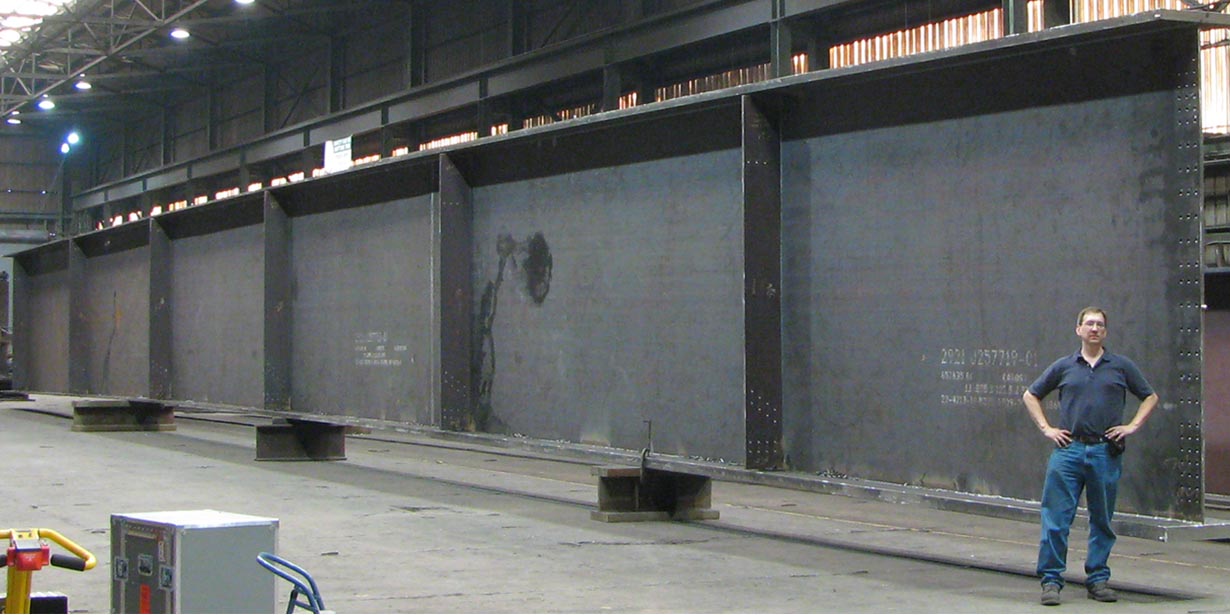

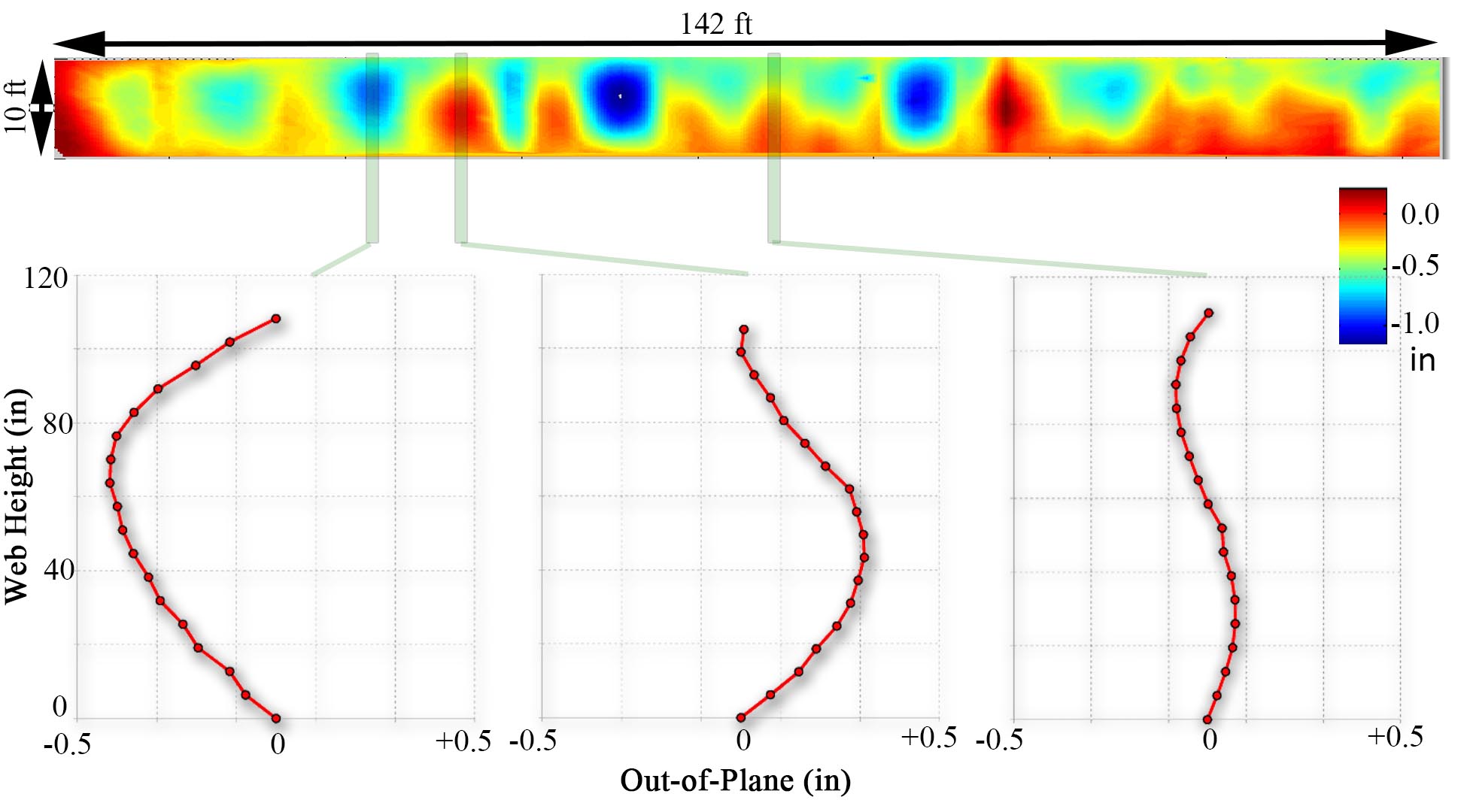

Fuchs Consulting, Inc. has developed a BRIDGE VIRTUAL ASSEMBLY SYSTEM (BRIDGE VAS)

that improves manufacturing processes and enhances quality control for steel

bridge fabrication. The system replaces conventional match-drilling with

virtual assembly methods, creating custom-designed splice plates. Vastly

improved measurement and documentation of fabricated girders is possible with

the system. This project report describes these improved measurements in

detail and compares them to conventional measurement methods, including a

detailed analysis of the accuracy limitations of current methods. An

assessment of current fabrication processes was conducted and is presented.

Based on this assessment, the measurement system was designed and tested; the

design features and a system description are provided within this report. The

system was deployed on a production bridge job, representing the first time

entire lines of girders have been measured with such precision and accuracy

and the first time virtual assembly has ever been demonstrated.

|

| |